Corrugated cardboard has become an increasingly important material in recent years, bolstered by a global movement away from plastics and towards more sustainable products. The particular versatility of cardboard and paper as packaging is putting the material in high demand for the foreseeable future, prompting new product innovations and advances in packaging machinery.

Corrugated Cardboard Industry Overview

The global market for corrugated cardboard packaging was valued at almost $183 billion in 2023 and is expected to exceed $220 billion by 2028. The e-commerce industry continues to grow after the substantial boost it received in 2020, leading to rising demand for packaging materials such as corrugated cardboard boxes and rolls. Global e-commerce is estimated to be in the trillions of dollars and is likely to double in value within the next 5-10 years.

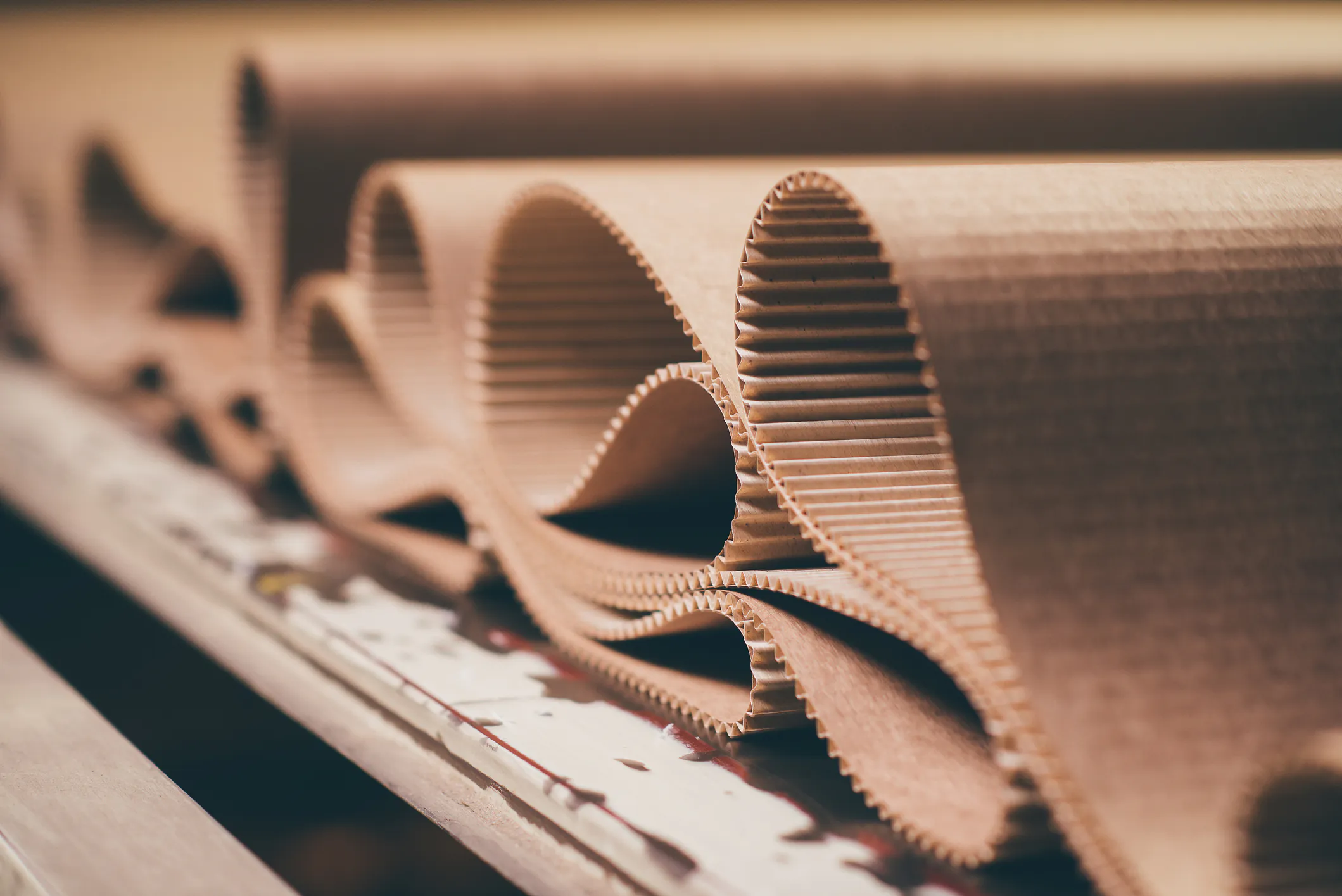

Corrugated cardboard is a popular choice for shipment packaging due in part to its fluting, which helps absorb shocks, insulate contents, withstand high pressure, and provide cushioning to the package’s contents. It also has a lower carbon footprint than many other types of packaging: not only is it renewable and recyclable, it’s also light and durable, reducing transportation costs and allowing for reuse before it reaches its end of life.

Product packaging is another major source of demand for corrugated cardboard. It can be made into many shapes depending on product requirements, and in some use cases is beginning to replace flexible plastic bags. It also takes well to multiple printing techniques. The food and beverage industry is increasing its use of corrugated cardboard for cartons, food trays, and many other types of packaging. The material can handle long shipping times and keep moisture away from products. It’s also a solid choice for products that need single-use secondary or tertiary packaging due to its sustainable nature. Many other sectors use corrugated cardboard packaging as well, from home appliances and electronics to beauty and healthcare products.

Corrugated Cardboard Packaging Trends

There are many factors impacting the corrugated cardboard industry, from external pressures to changing customer preferences to internal upgrades and process changes. Here are some of the trends manufacturers can expect to see over the next several years.

Sustainability

Concerns around sustainability are increasingly impacting manufacturers across sectors and around the world. There is growing pressure from both consumers and government regulators to reduce environmental impact in terms of resource use, waste, and carbon emissions, and businesses are making changes to the materials and processes they use in their operations.

While corrugated cardboard is already considered a sustainable product, that doesn’t mean the industry is unaffected by the current sustainability movement. Aside from a general increase in demand, customers are looking for new types of cardboard products with different use cases, shapes, and functionalities, such as specially lined or treated cardboard that can safely hold foods or even liquids.

The corrugated cardboard industry has also successfully decreased its greenhouse gas emissions over the past two decades, putting it at an advantage in terms of meeting government-set sustainability targets in countries that have made this a priority. Investments in clean energy sources can help manufacturers continue to reduce their environmental impact.

Demand for Lightweight Packaging

Lightweight packaging is becoming increasingly sought-after by businesses that need to transport significant quantities of products, particularly over long distances. Light packaging material reduces the weight of the products being shipped, which cuts down on the amount of fuel needed to transport them. Reducing fuel usage improves sustainability, but it also lowers shipping expenses at a time when material prices continue to fluctuate and supply chain challenges make certain items more expensive to obtain. Businesses are therefore seeking out packaging that weighs less while still protecting its contents during transportation.

Smart Packaging

Businesses are beginning to incorporate technology into packaging products for a variety of uses. Applications include up-to-the-minute tracking, monitoring temperature and humidity, impact detection, and more. Sensors, RFID tags, and QR codes are all being integrated into packaging products. This allows companies to easily determine if and where a shipment is delayed, whether items have been damaged in transit, and whether products have been kept in the right conditions to ensure proper quality and safety.

Automation

Industry 4.0 technologies such as automation are becoming increasingly popular among manufacturers, and can benefit the corrugated cardboard industry significantly. Automation reduces the amount of human labor needed to run a production line, allowing employees to focus on other, lower-risk tasks and making it easier for businesses to adapt to worker shortages. It also allows for detailed data collection and processing, which can be used to inform business decisions and provide more accurate predictions of demand and inventory levels. Manufacturers are therefore adopting automation technologies to improve efficiency, reduce downtime, and lower operational costs.

Custom Packaging Products

Because of the increasing number of companies that are replacing plastic packaging with more environmentally friendly alternatives, demand for customized cardboard packaging is rising significantly. Businesses are looking for packaging with particular shapes and properties, such as durability or moisture resistance. Custom-printed packaging is also in high demand, with digital printing technology making it easier than ever to tailor corrugated cardboard products to meet the marketing and design needs of clients.