The global apparel knitting industry is thriving, benefitting from the versatility of knitted fabrics and the wide range of materials they can be made from. Knitted fabric is a popular material for many different applications. Its elasticity, absorbency, breathability, and resistance to wrinkles makes it well-suited to sportswear, and it’s a common choice for undergarments such as underwear, bras, socks, and other hosiery.

The industry took a hit from COVID-19 disruptions to production and restricted consumer budgets, and the increase in remote work has impacted the type of clothing in demand from former office workers. Apparel knitting companies have had to adapt to these changing conditions.

Despite these challenges, the global market for knitwear was worth over half a trillion dollars in 2021, according to data from Transparency Research. By 2031 it’s expected to reach nearly a full trillion dollars, bolstered by demand for lightweight, high-performance clothing. While the monetary and environmental costs of cotton pose a challenge to the market, there are many other natural and synthetic fibers for knitwear companies to work with, allowing them to meet rising demand for sustainable products and processes.

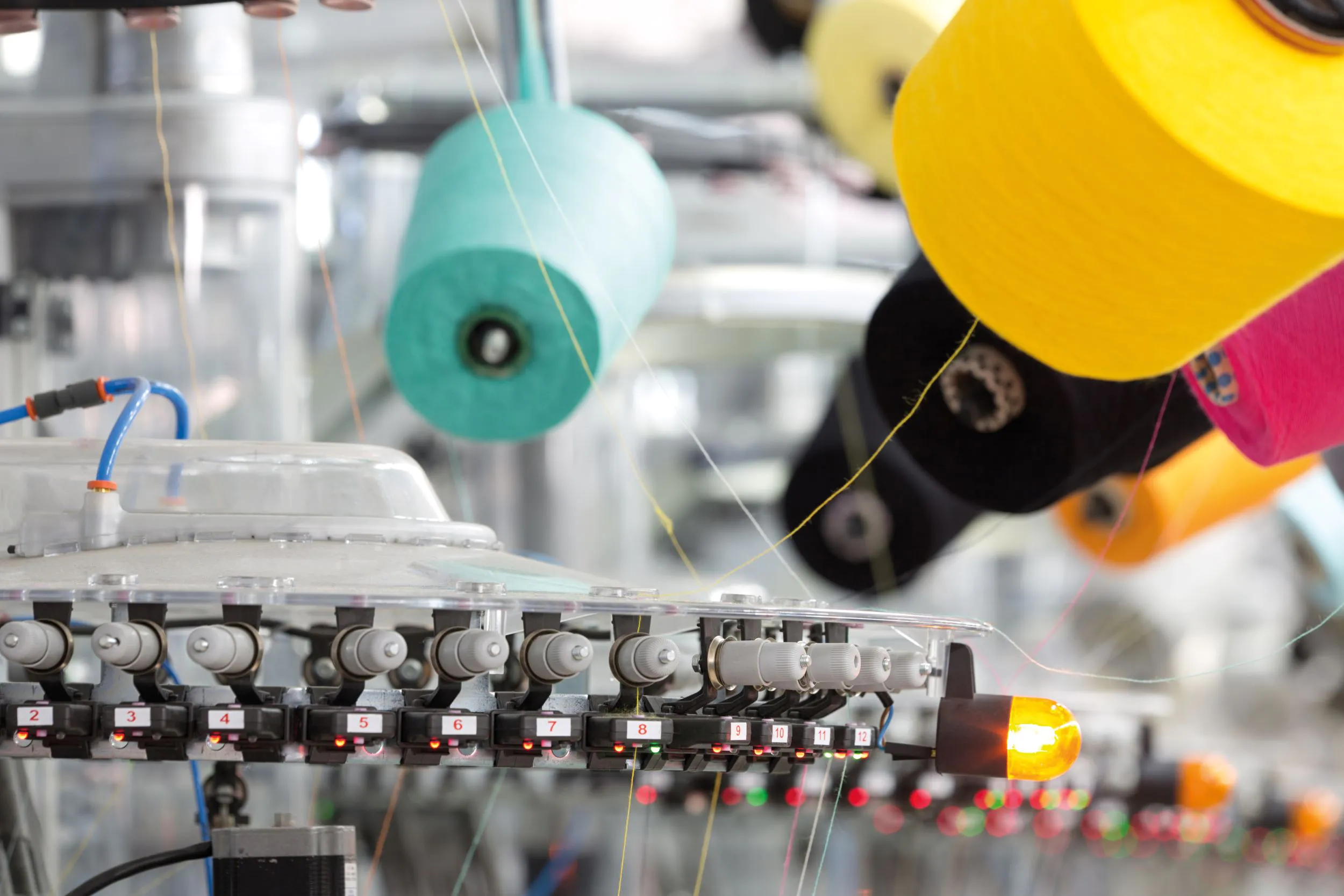

Technological innovations are also impacting the market, with machinery manufacturers and software developers creating products to improve efficiency, reduce errors, and explore new production methods. 3D printing and AI are two technologies that are currently influencing companies in the apparel knitting industry.

The Impact of 3D Printing on the Apparel Knitting Industry

Fashion designers and researchers have been experimenting with 3D-printed clothing for several years now, creating high-concept and high-fashion pieces. However, 3D printing doesn’t lend itself well to more practical garments — plastic and metal, the typical materials used in 3D printing, aren’t flexible or comfortable enough to work well as clothing. Most 3D printers also aren’t able to produce details that are fine enough for clothing, resulting in a garment that is heavy and with an unappealing texture.

However, this doesn’t mean that 3D printing is completely irrelevant to the apparel knitting industry. Building on the principles and technologies of 3D printers, companies have developed 3D knitting as a more practical garment manufacturing method.

Like 3D printing, the 3D knitting process starts with using CAD software to design a piece of knitwear and turning that design into something the machine can understand. The physical process of creating the item is different, however. Unlike 3D printing, which extrudes filament or powder to build up an object layer by layer, 3D knitting works with needles and threads to create a garment in a single pass.

Manufacturing knitwear offers some advantages over working with woven fabric, especially with 3D knitting. While some clothing may be made using fabric that was knit elsewhere, 3D knitted garments skip that step, turning yarn directly into a finished item and saving on shipping and labor costs as well as reducing the amount of emissions created in the transportation of raw materials and finished goods. This also means that there is little or no waste fabric left over, as production only uses exactly as much material as needed for the final garment. Knitwear materials are also easy to reuse if there’s a flaw in the product: the garment can be unravelled without damaging the thread used to make it.

3D knitting allows for on-demand, personalized products. Patterns can be modified to suit individual customer preferences in terms of fit and design, which gives these garments an edge over their mass-produced competition. And on-demand production is another way to reduce waste, as companies make only the amount of stock that has been purchased and don’t risk being stuck with unsold products that they need to get rid of. While 3D-printed knitwear may not be able to compete with mass-produced goods in terms of price, this is balanced out by the ability to attract customers who are willing to pay a higher price for personalized and sustainable products.

Error-Detecting AI Improves Knitwear Quality

Knitting machine manufacturer Pailung has developed a defect detection system using cameras and AI to improve manufacturing efficiency and reduce waste. In knitwear, defects such as snags and needle lines make a product unsuitable for sale and result in customer dissatisfaction if they reach the end user without being detected. The earlier such issues are caught, the less expensive they are to the manufacturer and the less likely they are to impact customers. When producing fabric in industrial quantities, it can be easy for human workers to miss small defects in large quantities of fabric. Machinery with built-in defect identification capabilities can flag this kind of issue before it becomes a larger problem, allowing the system to be shut down and the problem fixed quickly. This technology also allows apparel knitting companies to reduce the amount of human labor needed to monitor the process and inspect the fabric, saving on time and expenses. All of a company’s knitting machines can be monitored remotely from one station.